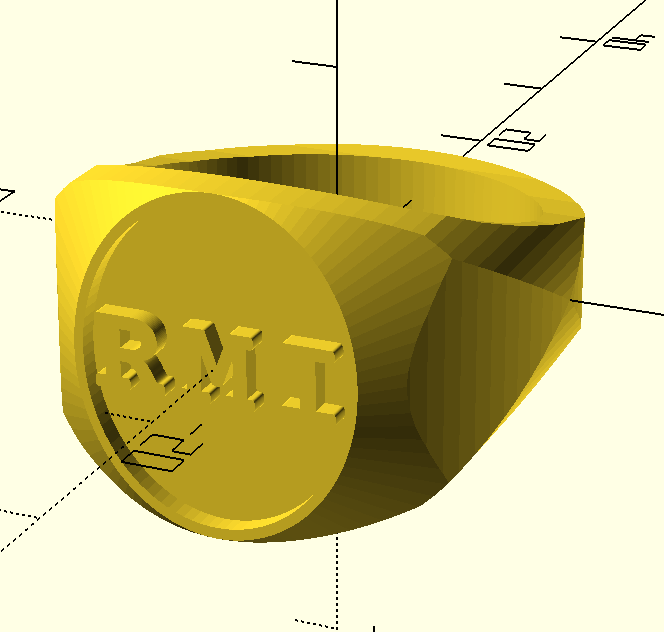

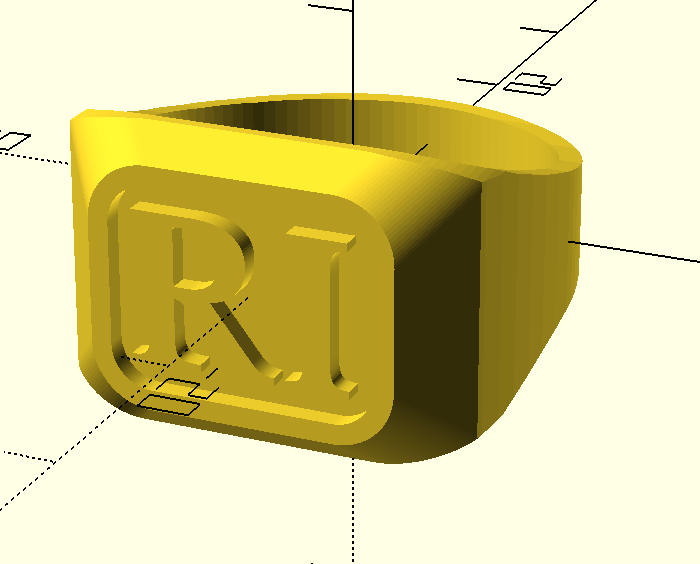

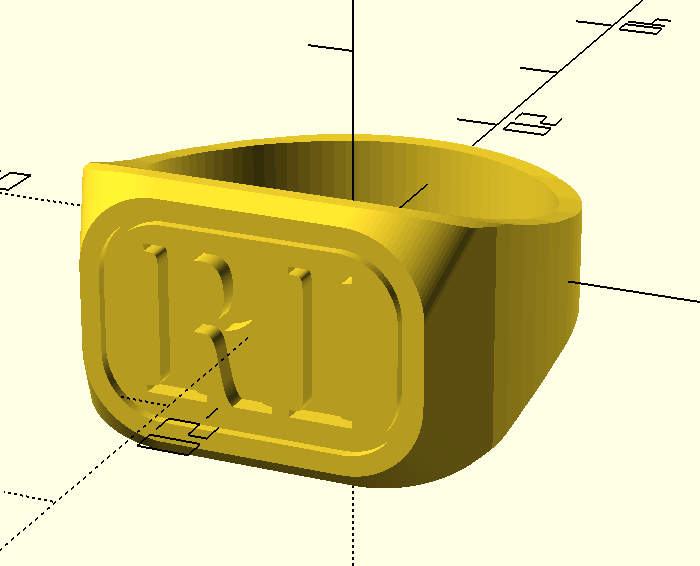

Even though I’m not much of a jewelry person, I had the idea to make a custom signet ring a few years back and I’ve been continually iterating on it since then. For those who don’t know what these are: in the past, they were used to sign documents by pressing the ring into a wax seal, leaving a unique impression. Nowadays, they’re mostly just a fashion statement.

Manufacturing

As with most of my 3d printing projects, I designed it using OpenSCAD. I use Shapeways to manufacture these since I don’t have the equipment to do metal printing/casting. They offer several different metals, ranging from very cost-effective plated metals to very prohibitively expensive solid gold or platinum.

Images

2022

2022 2023

2023 2024

2024Iteration

Over the years, I’ve tweaked the design and produced a new ‘edition’ for each year, with improvements based on things I liked & didn’t like about the last iteration. For example, for the 2022 version, I removed all of the super thin bezel portions that are prone to damage (I’m clumsy).

I’ve also made it progressively much lighter from version to version. The initial version was much thicker, kind of uncomfortable to wear. One of the main reasons for this is that was unsure what I could get away with for the thin-ness of the band while maintaining durability. The latest version was made this last December, and I’m thinking about what I’ll improve or change for version 4 for later this year.

This philosophy of iteration applies to tons of other things, especially software & product development. I’ve found it is much more productive when you can ship something, and test it in-market (or in this case, on my hand), and make incremental improvements. It’s also a great way to learn about the constraints, business needs, etc. of whatever you’re working on. Much better than cycles of designing and re-designing without ever shipping anything!